Shaft Collar

At SSJ, we use the strongest, highest quality materials to ensure optimum performance on all of our collars at competitive prices.

Learn more

contact us

Watch the video About Our Campany

SSJ in 1997 as Agknx, SSJ specialized in the design and manufacture of high performance collars and couplings. All products are carefully manufactured in Hangzhou, China under strict control using proprietary processes. For 3-D CAD files, full product specifications and other technical information.

Fast and free shipping within China.

Expedited or international shipping is available, please call us.

Set Collars & Shaft Collars

Set collars (also known as shaft collars) allow the user to position tools and attachments to a shaft. Using an adjustable screw, the set collar can be tightened securely and released freely.

HOW A SHAFT COLLAR WORKS

Commonly found in power transmission applications, shaft collars are ring-shaped plastic or metal devices that clamp around a shaft. The purpose of the collar is usually to hold motor components, gear assemblies, sprockets, bearings, and other parts in place and sometimes facilitate their proper movement. The collars may specifically locate components, keep them appropriately spaced, or limit their movement. Shaft collars may also be used to connect one end of the shaft itself to a part or surface.

The simplest shaft collars use set screws that tighten into the shaft to hold the collar in place. While these collars still see some use, the screws tend to mar the shaft which makes it difficult to remove and reposition the collars. Most modern shaft collars use a clamp that holds to the shaft. Clamp screws tighten the clamp around the shaft without the need to dig into the shaft itself.

There are multiple types of shaft collars, each suited to different purposes. Some of the most common types of shaft collars include:

- Hinge shaft collars have an open hinge on one side and a clamp screw on the other, enabling them to be easily assembled anywhere on the shaft. They are completely self-contained and eliminate the risk of dropping or losing screws.

- One-piece shaft collars feature improved performance, allowing an easy increase in clamping force by tightening the clamp screw.

- Two-piece shaft collars can be assembled anywhere on the shaft, including between other shaft collars.

Shaft collars are also available in multiple bore configurations, including round, threaded, hexagonal, and square. While off-the-shelf shaft collars are suitable for many needs, standard shaft collars can be altered to meet specific application needs. Fully customized shaft collars are also an option for unique situations.

What Are Shaft Collars?

Quick-Clamping

Quick-clamping collars are relatively new to the market and operate similarly to other clamping collars. They also do not mar the shaft. Their advantage over standard clamping collars is that they do not require tools to install or remove. They are ideal for light duty applications that require frequent setup changes or adjustments.

- Cam Lever quick-clamping collars operate with a low profile lever that controls their clamping forces. The integral handle sits flush with the outside diameter and can be finger actuated without tools for quick adjustments.

- Clamping Lever quick-clamping collars use an adjustable, removable lever that replaces standard collar hardware. The user can lift the handle and twist it to lock it in a new position with a ratcheting action.

Hinge

Hinge shaft collars allow for easy assembly and disassembly on the shaft. They are a single unit that can be installed without the risk of dropping loose components. They are often used when operating under strict time restrictions and in harsh environments.

Heavy Duty, Thin Line, and Double Wide

Heavy Duty shaft collars have greater widths and larger outer diameters to take advantage of the increased torque of larger screws. If increasing the outer diameter is not an option, increasing the width of the shaft collar enough to support additional screws can also be an effective way of increasing holding power.

have similar advantages to stacking several shaft collars and can increase holding power.

Thin Line shaft collars have reduced widths and smaller outer diameters making them a good option in applications with space or weight restrictions.

Bore Shape Varieties

Threaded Bore shaft collars provide exceptional axial holding power without damaging threaded shafts. Their simple and flexible design enables quick assembly and easy adjustments.

Round Bore shaft collars are used as stops, locators, spacers, and bearing faces for a wide range of motion control, power transmission, and mounting applications. They are suitable for use on shafts, piping, tubing, and split hubs.

Hexagonal (Hex) Bore and Square Bore shaft collars are manufactured to fit hexagonal or square shafts. They are non-marring and commonly used for agricultural or conveyor applications.

D-Bore clamp style shaft collars have a single flat in the bore and can be used in place of set screw shaft collars. When used on appropriate d-shafting, they offer higher holding power, even surface contact, and will not mar the shaft.

Keyed

Keyed shaft collars are used in positive drive applications to prevent slippage on the shaft. Other components can be mounted to the shaft collar to allow for the assembly to rotate with the shaft.

Mountable

Mountable shaft collars are used to mount sensors, fixtures, and other assemblies to shaft collars or to one another. The three different styles are outer diameter holes, outer diameter flats and holes, and quick release.

End-Stop Collars

End stop collars fit over rail assemblies on precision shafting.

|

Solid Single Piece – Zinc Plated and Stainless Steel

|

|

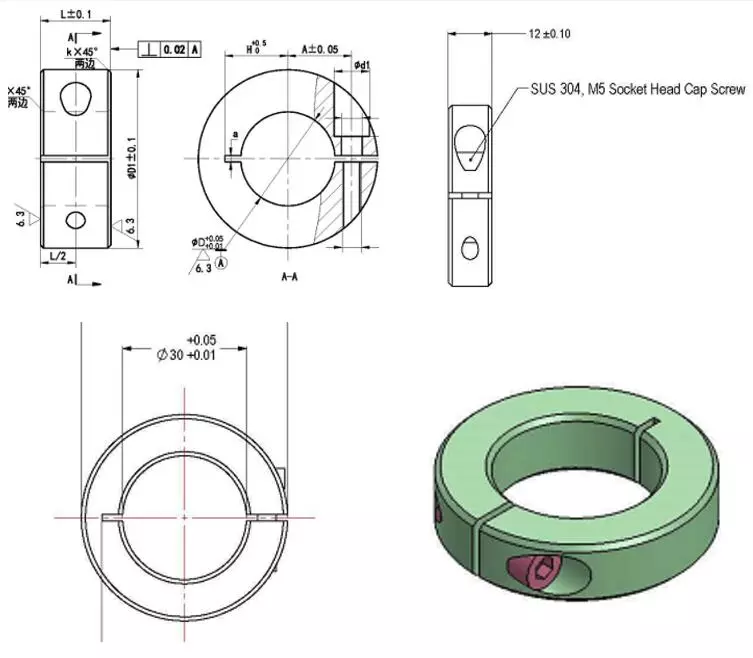

One-Piece Split Shaft

|

|

Two-Piece Split Shaft

|

Types of Shaft Collars

Shaft collars are usually made of aluminum, steel, stainless steel, or alloyed steel and coated with zinc, chromium, or black oxide. Shaft collars can also be made from non-metallic materials such as nylon.

Set Screw Collars

The first type of mass-produced shaft collars was set screw shaft collars. They were used primarily on line shafting in early manufacturing mills. Nowadays, set-screw collars are suitable for simple shaft positioning and shouldn’t be used for high axial loads or applications that require repositioning. Unfortunately, with these collars, the set screw can damage the shaft, causing a flare-up of the shaft’s material, which makes it difficult to adjust or remove the collar. To prevent this, tiny flats are often added onto the shaft at the set screw locations.

Clamping Style Collars

Clamp-style shaft collars were created to eliminate the problems connected to the set-screw collar. There are two types: one-piece and two-piece shaft collars. Instead of jutting into the shaft, the screws compress the collar and lock it into place. The shaft and the collar are linked with friction instead of protruding screws. This type of collar is still easy to use, but there is no potential shaft damage. With the screws compressing the collar, the force is distributed uniformly, which creates stronger holding power.

Although clamp-type collars work fine under relatively constant loads, sudden increases in force may make the collar move. This movement is because of the very high forces created by a relatively small mass during sudden impact compared to a gradual and steady force. If shock loads can’t be avoided, an undercut may be formed on the shaft, and a clamp collar can then be employed to create a positive stop that can stand up to shock loads without moving.

One-piece shaft collars, called c-style collars, have a simple design using a single screw. They surround the shaft with an evenly distributed compressive force. Because of their design, they cannot be disassembled, which means that they are only appropriately used when the end of the shaft is easily reached.

Two-piece shaft collars can be disassembled entirely, allowing them to be used in situations where the end of the shaft is not accessible. Two-piece collars also provide a higher and more uniform holding force and shock-load resistance compared to one-piece collars since they can use their full seating torque to provide compressive forces around the shaft. They also accept more significant variances in shaft diameter and can be assembled anywhere on a pole.

Quick-clamping collars are a variation of the one-piece collar. The main difference is that instead of tightening a screw, a lever is used to open and close the collar. This is much faster and does not require any tools.

Axial Shaft Collars

Another type of shaft collar is where a single bolt and nut surround the shaft. The bolt, acting as the exterior thread, has kerf cuts along it that act like fingers, which are then compressed onto the shaft as a nut is tightened over it. These are used in applications such as on-camera tripod legs. If wrench-tightened, these can be very tight.

Threaded Shaft Collars

Threaded collars have threaded interiors so that they can be used on threaded shafts. The threads make them a good choice for heavy-load applications that require high axial holding power. They are also easily adjusted and can be positioned precisely.

Production Workshop

Set Collars or shaft collars as they are also known, allow the user to position components to a shaft, such as tools, fittings, or machinery and transmission including bearings, gearboxes and motors. Using an adjustable grub screw or a soft tipped threaded adjusting handle, the set collar can be tightened securely and released freely.WDS also stocks a range of shaft collars in various styles including standard fit, semi-split, double-split, threaded and keywayed models.

Company News

China manufacturer Cast Iron Grey Iron Casting Gg20 Gg25 Gg30 CNC Machining Retaining Clamp shaft collar design

China factory GS-44X34.5 Aluminum Alloy Single Diaphragm Clamping Couplin CZPT shaft collar

China manufacturer Standard Nonstandard Single Split Shaft Collar Stainless Steel Black Coating Shaft Collar Clamps axle shaft collar

Why choose us?

Quality

You expect reliable, safe and durable equipment. Our focus on quality and continuous improvement gives you the best solutions available today.

Custom Made

Your device is unique. Our talented team of engineers can customize solutions to meet your exact specifications for optimal design flexibility.

Professional Knowledge

Superior design ensures superior performance. Since its inception, SSJ has led the industry in innovation dynamics.